ALS PLU-926 Pallet Labeller

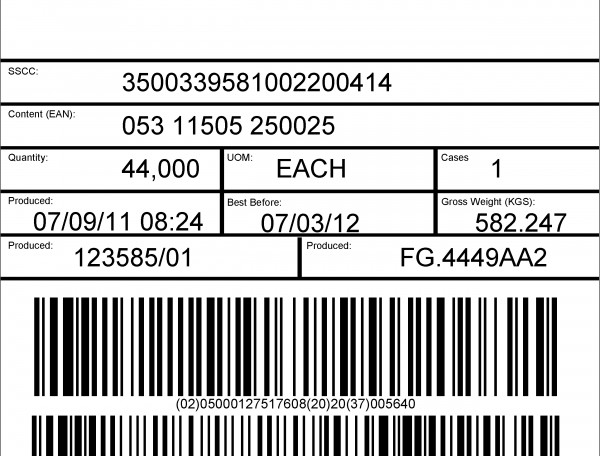

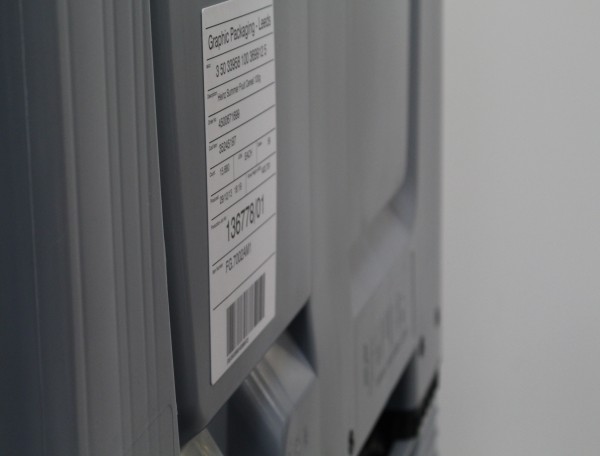

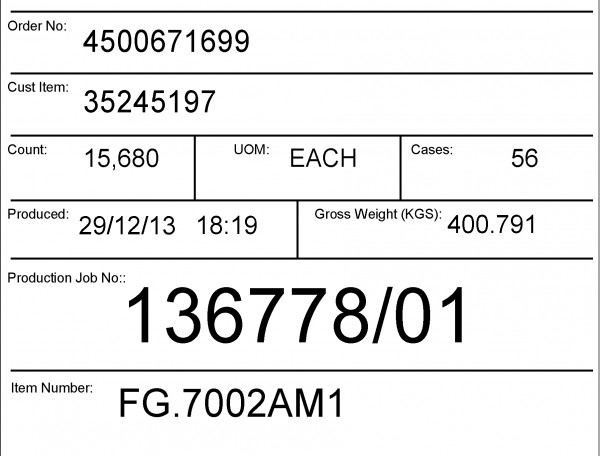

The PLU-926 pallet labeller has been designed as a high functioning industrial machine. Our pallet labellers print and apply A5 format GS1 pallet labels onto two adjacent faces of a pallet including Serial Shipping Container Codes (SSCC) in accordance with the GS1-128 barcode standards. This is the company’s 3rd generation of automatic unattended pallet labelling machines.

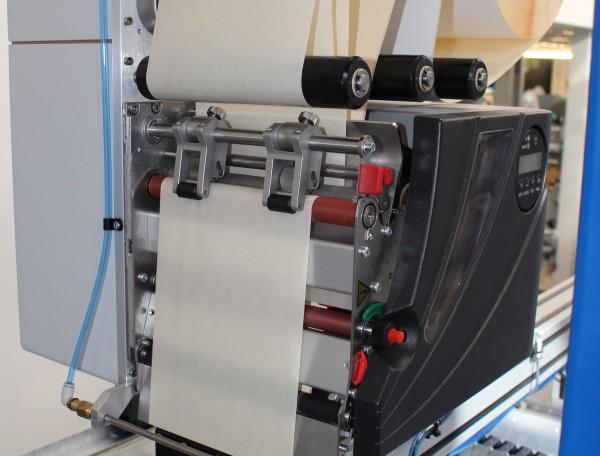

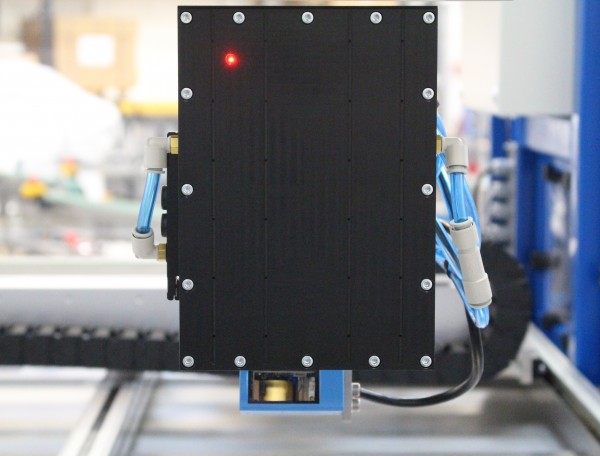

Our automatic pallet labellers use heavy-duty components throughout, including an industrial thermal transfer engine to print and apply two or three GS1-compliant pallet labels onto adjacent sides of a pallet using a tri-axis moving head applicator. Two sides are applied when the pallet is stationary, while the third (if required), is applied after the pallet is advanced to a secondary stop position, all under PLC control. The featured barcode scanner confirms that labels have been applied well and scan accurately. A label-on-pad sensor detects that a label is present during each labelling cycle and the system can be programmed to have up to three re-tries if label application is not verified for any reason. This eliminates the chance of an unlabelled pallet being released. Naturally, all access doors and panels are fully guarded and interlocked.

The PLU-926 Pallet Labeller by ALS is a comprehensive automatic pallet labelling system that has an industrial design and offers a choice of Print Engines. The standard machine uses the XPA 934 model.

Designed to integrate with your existing line control hardware and pallet tracking software, contact to us now and discover how we can help improve your pallet labelling efficiency.

Take a look at our very own ALS PLU-926 Pallet Labeller below.

GS1 Partner

If you need help producing your barcode pallet labels, then since ALS is a GS1 UK Partner, you know you are getting the best advice. ALS also manufacture labels and sell thermal transfer ribbons for use in all pallet labelling machines.